UL certificated List

| Item | Standard | Product Category | File Number | Model Number(s) |

| 1 | UL44 | Thermoset-insulated wire | E497639 | RHW, RHW-2, XHH, XHHW, XHHW-2, RHH |

| 2 | UL62 | Flexible Cord | E476174 | SPT-2, SPT-3, SPT-1 |

| 3 | UL62

CSA C22.2 No. 49 |

Flexible Cord Certified for Canada | E476174 | SPT-2, SPT-3, SPT-1 |

| 4 | UL62

CSA C22.2 No.49 |

Flexible Cords and Cables | E476174 | USL, CNL: Thermoset Jacketed Cord, Types SJ, S, SJO, SO, SJOO, SOO, SJOW, SOW,SJOOWand SOOW. |

| 5 | UL62

CSA C22.2 No. 49 |

Electric Vehicle Cable Certified for Canada | E476173 | EVE, EVJE, EVJT, EVT |

| 6 | UL 758

CSA C22.2 No. 210 |

Appliance Wiring Material Certified for Canada – Component | E465725 | AWM Class I, II or I/II, Group A, B or A/B |

| 7 | UL 758 | Appliance Wiring Material – Component | E465725 | 1.Single-conductor, thermoplastic insulation.

2.Multiple-conductor, thermoplastic insulation. 3.Single-conductor, thermoset insulation. |

| 8 | UL 83 | Thermoplastic-insulated Wire | E493062 | THHN, THWN-2, THHW, THW, THW-2, TW, THWN |

| 9 | UL 83

CSA C22.2 No. 75 |

Thermoplastic-insulated Wire Certified for Canada | E493062 | T90 Nylon, TWN75, TWU75, TW, TW75, TWU |

| 10 | UL44

UL854 |

Service-entrance Cable | E497640 | USE, USE-2, Type SE- STYLE R (SER), Type SE- STYLE U (SEU) |

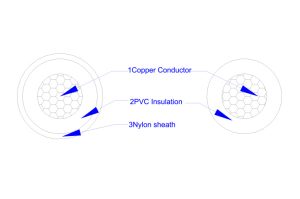

Table 1 THHN

| Cross section area | Stranding | Average thickness of insulation | Min. thickness of nylon layer | Approx. overall diameter | Approx. weight |

| AWG/kcmil | No. | mm | mm | mm | Kg/km |

| 14 | 7 | 0.38 | 0.1 | 3.06 | 25.55 |

| 12 | 7 | 0.38 | 0.1 | 3.51 | 37.12 |

| 10 | 7 | 0.51 | 0.1 | 4.4 | 59.71 |

| 8 | 7 | 0.76 | 0.13 | 5.73 | 96.92 |

| 6 | 7 | 0.76 | 0.13 | 6.72 | 147.36 |

| 4 | 7 | 1.02 | 0.15 | 8.48 | 233.79 |

| 2 | 7 | 1.02 | 0.15 | 10.01 | 355.45 |

| 1 | 19 | 1.27 | 0.18 | 11.61 | 458.67 |

| 1/0 | 19 | 1.27 | 0.18 | 12.61 | 562.76 |

| 2/0 | 19 | 1.27 | 0.18 | 13.81 | 701.95 |

| 3/0 | 19 | 1.27 | 0.18 | 15.11 | 870.34 |

| 4/0 | 19 | 1.27 | 0.18 | 16.56 | 1079.74 |

| 250MCM | 37 | 1.52 | 0.2 | 18.33 | 1290.64 |

| 300MCM | 37 | 1.52 | 0.2 | 19.73 | 1533.34 |

| 350MCM | 37 | 1.52 | 0.2 | 20.99 | 1769.79 |

| 400MCM | 37 | 1.52 | 0.2 | 22.18 | 2008.78 |

| 500MCM | 37 | 1.52 | 0.2 | 24.35 | 2483.8 |

| 600MCM | 61 | 1.78 | 0.23 | 26.98 | 3003.7 |

| 650MCM | 61 | 1.78 | 0.23 | 27.88 | 3235.88 |

| 800MCM | 61 | 1.78 | 0.23 | 30.49 | 3958.32 |

| 1000MCM | 61 | 1.78 | 0.23 | 33.55 | 4898.37 |

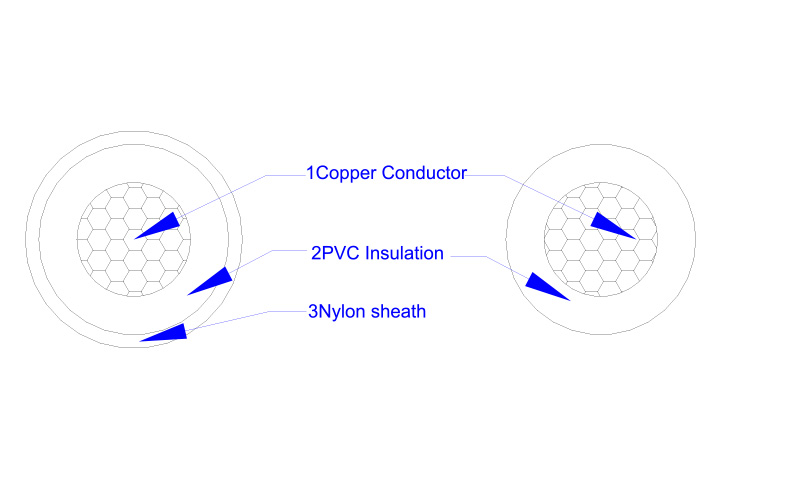

Table 2 THW

| Cross section area | Stranding | Average thickness of insulation | Approx. overall diameter | Approx. weight |

| AWG/kcmil | No. | mm | mm | Kg/km |

| 14 | 7 | 0.76 | 3.4 | 28.8 |

| 12 | 7 | 0.76 | 3.8 | 40.9 |

| 10 | 7 | 0.76 | 4.5 | 61.5 |

| 8 | 7 | 1.14 | 6.0 | 102.1 |

| 6 | 7 | 1.52 | 7.7 | 167.0 |

| 4 | 7 | 1.52 | 8.9 | 245.9 |

| 2 | 7 | 1.52 | 10.5 | 369.6 |

| 1 | 19 | 2.03 | 12.5 | 489.2 |

| 1/0 | 19 | 2.03 | 13.5 | 595.8 |

| 2/0 | 19 | 2.03 | 14.7 | 738.0 |

| 3/0 | 19 | 2.03 | 16.0 | 909.7 |

| 4/0 | 19 | 2.03 | 17.5 | 1122.7 |

| 250MCM | 37 | 2.41 | 19.5 | 1348.8 |

| 300MCM | 37 | 2.41 | 20.9 | 1595.8 |

| 350MCM | 37 | 2.41 | 22.1 | 1836.1 |

| 400MCM | 37 | 2.41 | 23.3 | 2078.7 |

| 500MCM | 37 | 2.41 | 25.5 | 2560.4 |

| 600MCM | 61 | 2.79 | 28.3 | 3100.6 |

| 650MCM | 61 | 2.79 | 29.2 | 3335.9 |

| 800MCM | 61 | 2.79 | 31.8 | 4067.4 |

| 1000MCM | 61 | 2.79 | 34.8 | 5018.1 |