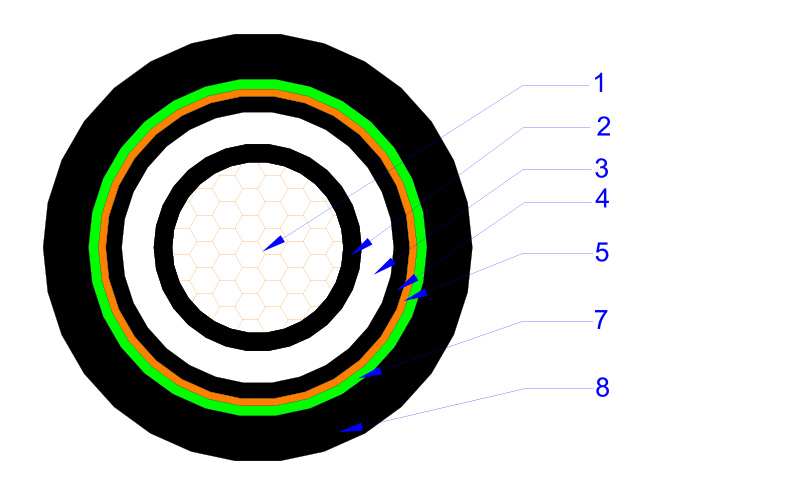

Table 1 Single core CU(AL)/XLPE/CTS/PVC

| No. & CSA |

Conductor | XLPE insulation | Copper tape screen | Outer sheath | Weight kg/km | ||

| Approx. diameter mm | Nominal thickness mm | Nominal thickness mm | Nominal thickness mm | Diameter mm | YJV(CU) | YJLV(AL) | |

| 1*25 | 6 | 5.5 | 0.12 | 1.7 | 23.84 | 759.2 | 606.7 |

| 1*35 | 7 | 5.5 | 0.12 | 1.8 | 25.04 | 890.7 | 678.2 |

| 1*50 | 8.2 | 5.5 | 0.12 | 1.8 | 26.24 | 1039.6 | 752.2 |

| 1*70 | 10 | 5.5 | 0.12 | 1.9 | 28.24 | 1307.5 | 885.7 |

| 1*95 | 11.6 | 5.5 | 0.12 | 1.9 | 29.84 | 1590.1 | 1010.2 |

| 1*120 | 13 | 5.5 | 0.12 | 2 | 31.44 | 1870.4 | 1139.3 |

| 1*150 | 14.6 | 5.5 | 0.12 | 2 | 33.04 | 2187.2 | 1274.9 |

| 1*185 | 16.2 | 5.5 | 0.12 | 2.1 | 34.84 | 2582.7 | 1445.4 |

| 1*240 | 18.4 | 5.5 | 0.12 | 2.2 | 37.24 | 3163.1 | 1688.4 |

| 1*300 | 20.6 | 5.5 | 0.12 | 2.2 | 39.44 | 3772.4 | 1929 |

| 1*400 | 23.8 | 5.5 | 0.12 | 2.3 | 42.84 | 4724.5 | 2312.4 |

| 1*500 | 26.6 | 5.5 | 0.12 | 2.4 | 46.08 | 5801.6 | 2739.6 |

| 1*630 | 30 | 5.5 | 0.12 | 2.5 | 49.68 | 7181.5 | 3263.4 |

| 1*800 | 34 | 5.5 | 0.12 | 2.7 | 54.08 | 8917.8 | 3931.2 |

Table 2 Three core CU(AL)/XLPE/CTS/PVC

| No. & CSA |

Conductor | XLPE insulation | Copper tape screen | Outer sheath | Weight kg/km | ||

| Approx. diameter mm | Nominal thickness mm | Nominal thickness mm | Nominal thickness mm | Diameter mm | YJV(CU) | YJLV(AL) | |

| 3*25 | 6 | 5.5 | 0.1 | 2.6 | 48.8 | 2562 | 2102 |

| 3*35 | 7 | 5.5 | 0.1 | 2.6 | 51 | 2956 | 2315 |

| 3*50 | 8.2 | 5.5 | 0.1 | 2.7 | 53.8 | 3465 | 2598 |

| 3*70 | 10 | 5.5 | 0.1 | 2.8 | 57.8 | 4314 | 3042 |

| 3*95 | 11.6 | 5.5 | 0.1 | 3 | 61.7 | 5281 | 3533 |

| 3*120 | 13 | 5.5 | 0.1 | 3.1 | 64.9 | 6166 | 3961 |

| 3*150 | 14.6 | 5.5 | 0.1 | 3.2 | 68.6 | 7220 | 4469 |

| 3*185 | 16.2 | 5.5 | 0.1 | 3.3 | 72.2 | 8464 | 5035 |

| 3*240 | 18.4 | 5.5 | 0.1 | 3.5 | 77.4 | 10338 | 5892 |

| 3*300 | 20.6 | 5.5 | 0.1 | 3.6 | 82.3 | 12319 | 6761 |

| 3*400 | 23.8 | 5.5 | 0.1 | 3.8 | 89.6 | 15388 | 8115 |

| 3*500 | 26.6 | 5.5 | 0.1 | 4 | 96.6 | 18844 | 9613 |

| 3*630 | 30 | 5.5 | 0.1 | 4.3 | 104.6 | 23307 | 11495 |

| 3*800 | 34 | 5.5 | 0.1 | 4.5 | 113.6 | 28782 | 13748 |